Protecting and enhancing the values of sustainable working forests.

WASHINGTON FOREST PROTECTION ASSOCIATION

Forest Products and Jobs

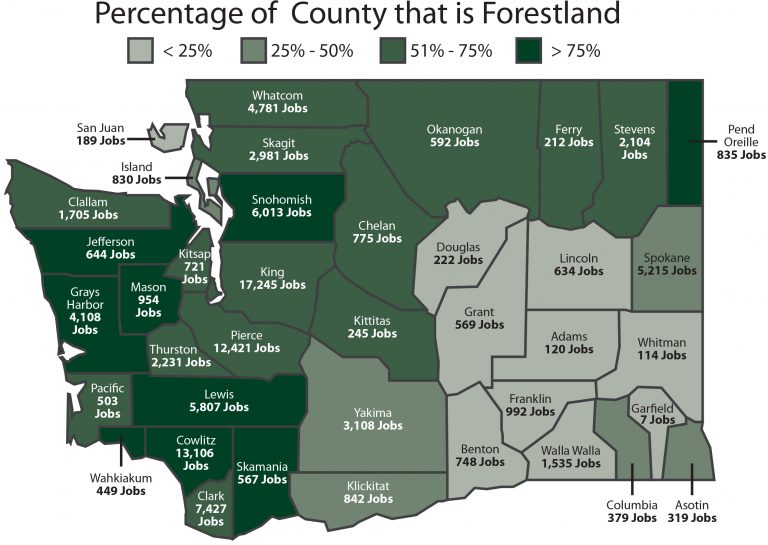

Working forests form the foundation of the timber industry that supports more than 102,000 workers and generates $6 billion in wages annually.

Continuous Technological Advancements

Meeting the demands of today’s complex forestry environment necessitates ongoing improvements in timber production methods while minimizing environmental impacts. A deeper understanding of forestry science drives technological innovation, often leading to the adoption of new surveying, planting, and harvesting technologies. The combination of these factors, coupled with the ingenuity of forest managers, ensures that technological innovation remains a vital aspect of forest management.

Forests, Wood, and Paper Products as Carbon Solutions

Private forests in Washington state contribute significantly to reducing carbon emissions, sequestering approximately 12% of the state’s emissions. Sustainable forest management provides a renewable timber supply that retains carbon throughout the lifespan of wood products, making forestry an effective natural carbon sequestration method.

21st Century Forestry Prioritizes Productivity and Conservation

Modern forestry practices prioritize efficiency and ecological conservation. Foresters maximize resource utilization at every stage, from tree nurseries to mills. Technological advancements have opened new avenues for 21st-century forestry, driven by the industry’s commitment to meeting public demand for sustainable wood and paper while minimizing ecological impact.

Key Technological Innovations include:

Biotechnology Advances in tree genetics promote uniform wood quality and reduce energy consumption during harvesting and processing. Disease and insect-resistant tree varieties are also developed.

Mechanized Harvesting Systems, Systems like Tree Length and Cut to Length enhance efficiency, safety, and lower production costs, reducing soil compaction.

Geographic Information Systems (GIS) GIS tools help forest managers monitor and model working forests, analyzing factors such as forest health, erosion trends, land boundaries, and road routing.

Laser Rangefinders Handheld lasers are used for precise measurements within tree stands, crucial for surveying and mapping Washington’s working forests.

Sawmill Technology, Scanners and automated handling systems maximize wood volume and value from each tree, allowing the use of smaller, faster-growing trees and lower-grade wood in engineered products. Environmental concerns are addressed through technologies like thermal oxidization and e-tubes.