Forest Management

Discover the everyday tasks of foresters as they work in the woods to manage forests and create wood and paper products.

did you know?

Trees are not just for lumber; they contribute to over 5,000 different products, including resins, glues, cosmetics, and food. The cellulose fibers in wood, bound together by lignin, are found in various items like rayon fabric, toothpaste, football helmets, and pizza boxes. Healthy trees absorb & store carbon dioxide. Using forest products reduce our carbon footprint.

Look around you…how many products are made from trees? You might be surprised, check out this list of products made from trees.

Lignin is a natural substance found in trees that, along with cellulose fibers, provides strength to the tree, making it suitable for construction and furniture. When wood is heated, cellulose separates from lignin, forming wood pulp used in paper production. Lignin can also be utilized to produce various chemicals for items like cosmetics, medications, and certain foods.

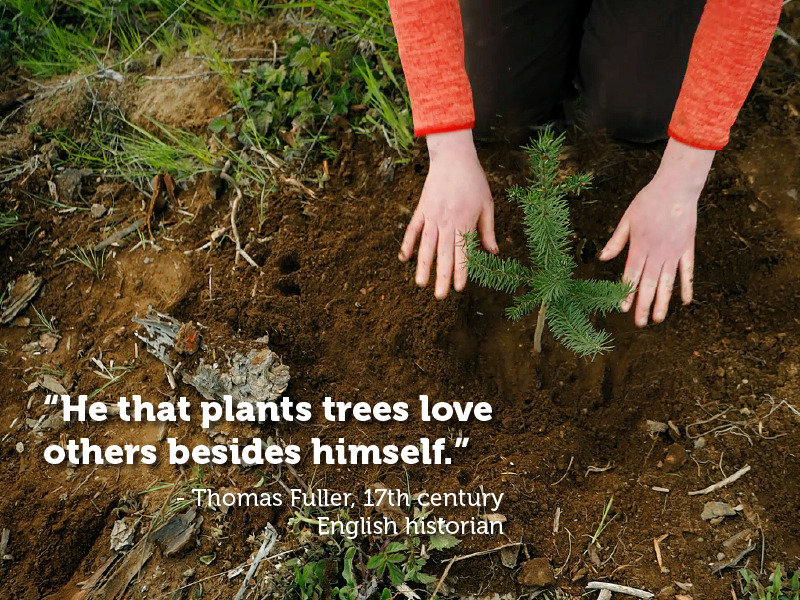

Tree planting

Following tree harvesting, reforestation efforts kick in. Tree planters reestablish forests by planting seedlings, with some tree planters planting up to 1,500 seedlings in a single day. In Washington's working forests alone, more than 52 million trees are planted annually. The nation's first tree farm was established in Montesano, WA in 1941.

On flat growing ground, an experienced tree planter might plant up to 1,500 trees per day.

Most of the trees that are planted get their start in a seedling nursery, where they are cared for up to 3 years before they are planted in the forest.

wood products

Wood and paper products are a part of our daily lives. Working foresters oversee the growth, management, and harvesting of trees to produce renewable and recyclable wood and paper products. Sustainable forestry includes long-term planning to determine which areas to harvest and which to preserve for wildlife habitat and water conservation.

Every part of the tree is utilized. Small trees require years of care and growth before they become suitable for harvesting. Once the timber arrives at the sawmill, it is processed efficiently to maximize lumber production. Additionally, the bark, wood chips, and sawdust are repurposed for making paper products, and the remaining wood residuals are used for bio-energy production.

A single tree can absorb more than 10 pounds of carbon dioxide, or CO2 each year. When the tree is harvested, the carbon is stored in wood. The only building material that is grown by the sun is wood. Using renewable wood helps us reduce our carbon footprint.

foresters corner

MANAGED FORESTS FAQs

Absolutely. Washington’s working forests plant three trees for every one tree harvested, ensuring a renewable supply of timber products for generations to come.

No – carbon stays in harvested wood products. Whether trees are standing tall in the forest, or the wood is used to build homes and skyscrapers, trees store carbon in the wood.

When trees are harvested, carbon stays in the wood, branches, needles, and bark. Healthy managed forests absorb twice the carbon and hold onto three times the carbon as unmanaged forests.

Not unless they are left in the forest to decay or burn. Wood stores carbon and wood products store carbon for the life of the useful product. The Pacific Northwest produces the highest level of softwood lumber in the nation, storing carbon for 80-100 years in lumber used for building homes, and engineered wood products such as Cross Laminated Timber (CLT) used to build buildings.

The carbon a tree stores while it is growing in the forest remains locked in the trunk, branches, roots and leaves even after it is harvested. In fact, stored carbon makes up half of wood’s weight, making durable timber products like buildings, furniture, toys, musical instruments and anything else made of wood carbon sinks.

Absolutely. Trees are a renewable resource. In fact, the trees harvested from Washington’s working forests today were planted 30 to 50 years ago knowing that they would one day be gathered to provide society with an environmentally friendly material for shelter, public infrastructure and other products that enhance our quality of life. It is this forward-thinking approach that ensures a sustainable supply of timber and other wood products for future generations.

That is an oversimplification that falls short of accurately describing the sustainable forestry approaches Washington’s working forests adhere to. Before a planned harvest, working forests identify riparian buffers, wetlands, steep slopes and other protected areas to avoid. Once these safeguarded areas are set aside, working forests sustainably harvest the land.

No. In forestry speak, the process of cutting trees on working forest lands is called harvesting. It is part of continual cycle of planting, harvesting and replanting to provide a sustainable supply of wood and wood products that benefit communities, our economy, the environment and wildlife.

Untrue. Manufacturing steel, concrete and plastic are high energy-intensive and carbon-intensive processes. Timber, on the other hand, is renewable and environmentally friendly because it takes far less energy and fossil fuel to produce wood products.

Absolutely. Sustainable timber harvesting mimic natural disturbances, benefiting small and large animals. For example, open areas created after provide grass and small plants for large mammals like elk to forage. In protected areas, working forests use science-backed approaches to both keep our state’s endangered and threatened species safe and keep wildlife habitat healthy.

Sustainable forestry is not about leaving forests untouched. Washington’s working forests strike a commonsense balance benefit the environment, wildlife, economy and society through responsible and sustainable forest management approaches.

Definitely not. The past decade of large-scale wildfires has made abundantly clear that leaving forests untouched and unmanaged can lead to catastrophic consequences. We need look no further than federally owned forests where densely packed forests have created dangerous fuel loads. Managed forests are healthy forests that are more resilient during times of stress like drought, extreme heat, infestation and disease.

Forest management ensures sustainable practices that benefit both the environment and our daily lives.

What is a Working Forest?

Foresters cultivate and manage trees in managed forests, starting with seedlings raised in nurseries. These small trees are then planted in forest soil, growing for decades until they are ready for harvest. Every part of a harvested tree is used, providing habitat for wildlife and enriching the soil for future generations. On average, 82% of the harvested tree is used to make forest products and 18% remains on the forest floor.

Any part of the tree left over provides habitat for wildlife and enriches the soil for the next generation of forest. Logs become the building materials for our homes and the furniture for our houses. Wood chips are used in the pulp and paper making process and for boxes, packaging and writing paper. Bark, branches and sawdust is used as fuel for energy and landscaping in our yards.

Forest management ensures sustainable practices that benefit both the environment and our daily lives.

Can you identify these tree species?

Learn more about the different trees species in Washington’s forests.