Cities of the future will rely on innovative products generated by the timber industry, according to Sidewalk Labs, a subsidiary of Google parent company Alphabet Inc.

Sidewalks Labs unveiled Sidewalk Toronto – an ambitious plan that aims to transform a portion of the eastern waterfront (12 acres) within the major Canadian city into a global model for sustainable, inclusive and inventive growth. The Sidewalk Toronto Master Innovation Development Plan is centered around five main themes: sustainability, economic vitality, housing affordability, mobility and nurturing an environment that supports innovation.

The planning of Sidewalk Toronto would include a robust transit system, ample pedestrian and bike-friendly infrastructure, ride sharing, and autonomous vehicles, thus reducing the need for households to own a car. The plan also calls for intentional design of public spaces like streets, parks and open spaces that ensure accessibility for the entire community and encourage people to spend more time outdoors together. That includes sidewalks filled with twice the number of trees currently found in major cities.

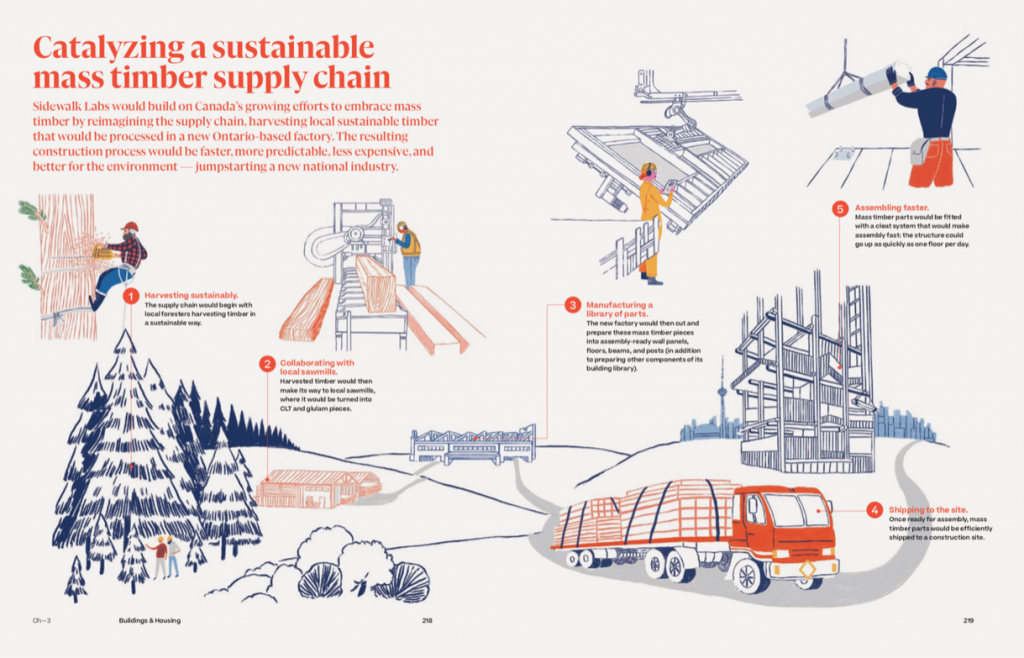

To promote affordability and sustainability, the high-tech community would rely heavily on mass timber products like cross-laminated timber and glue-laminated timber to make its eco-friendly and energy-efficient buildings. Sidewalk Toronto supporters also note that new wood materials would be an integral part in helping the development meet its bold affordable housing goals. Using factory-based construction and applying innovations that help streamline housing production, assembly and overall costs.

To make this happen, however, a story in Fast Company sites that: “Sidewalk Labs proposes investing $80 million to build a timber factory and supply chain that would support its fully timber neighborhood.”

According to Fast Company:

The company says the factory, which would be focused on manufacturing prefabricated building pieces that could then be assembled into fully modular buildings on site, could reduce building time by 35% compared to more traditional building methods.

“We would fund the creation of [a factory] somewhere in the greater Toronto area that we think could play a role in catalyzing a new industry around mass timber,” says Sidewalk Labs CEO and chairman Dan Doctoroff.

Sidewalk Labs estimates that the mass timber factory would create an estimated 2,500 jobs over the 20 years of the Sidewalk Toronto development and generate more than $1.4 billion in support of affordable and below-market housing through 2048. The timber would be sourced from spruce and fir trees forests in Ontario, Quebec and British Columbia.

Using emerging materials like cross-laminated timber, which is easier to manufacture and better for the environment than concrete or steel and yet just as strong and fire-resistant is growing in popularity in North America. Mass timber products also offer environmental benefits. Wood is a renewable resource that removes carbon dioxide gas from the atmosphere and continues to hold carbon even after harvesting.

CLT has been used in other parts of the world for more than two decades, but the appeal of CLT and other engineered woods has continued to grow as developers, architects and builders become more familiar with the benefits of this innovative wood product.

The next step for Sidewalk Toronto is a public comment period and working with the Canadian government to gain approval.